The Role of Welded Wire Mesh Panels in Food Processing Facilities

Introduction:

Within these facilities, welded wire mesh panels play a critical role in maintaining hygienic conditions, facilitating efficient operations, and ensuring the integrity of food products. In this article, we will explore the diverse applications and benefits of welded wire mesh panels in food processing facilities and their indispensable role in upholding food safety regulations.

Hygienic Food Handling:

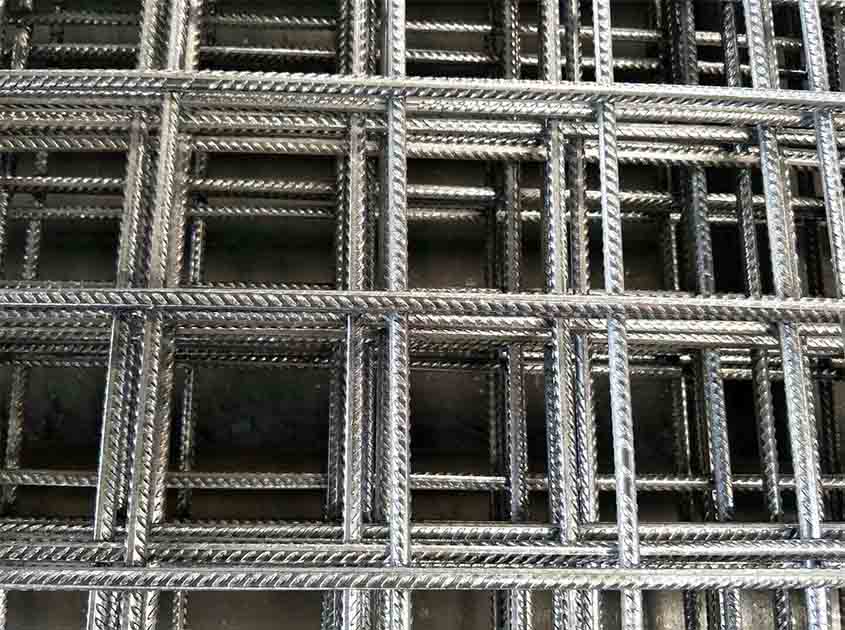

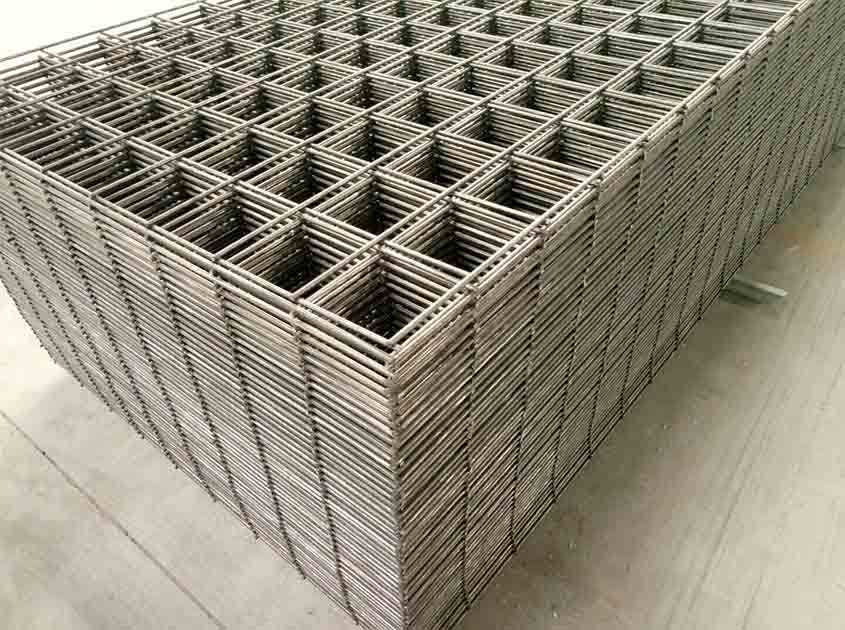

Hygiene is of utmost importance in food processing facilities. Welded wire mesh panels create a barrier between different sections of the facility, preventing cross-contamination and maintaining strict sanitary conditions. These panels are commonly used to construct walls, partitions, and ceilings, ensuring separation between processing areas, storage, and packaging zones, thus minimizing the risk of microbial contamination.

Robust Structural Support:

Welded wire mesh panels provide robust structural support within food processing facilities. They are used to create sturdy shelves, platforms, and storage systems, allowing for organized and efficient utilization of space. These panels can withstand heavy loads, ensuring the safe storage of raw materials, ingredients, and finished products, while optimizing the workflow and minimizing the risk of accidents or damage.

Air Circulation and Ventilation:

Proper air circulation is essential to maintaining the quality and freshness of food products. Welded wire mesh panels with their open-weave design allow for adequate airflow, promoting ventilation and reducing the buildup of excess heat and humidity. This feature helps prevent the growth of bacteria, mold, and other contaminants, contributing to the preservation of product quality and extending shelf life.

Effective Pest Control:

Food processing facilities are prone to pest infestations, which can have serious consequences for product safety and hygiene. Welded wire mesh panels are utilized to secure openings, such as windows, vents, and entry points, preventing the entry of pests into the facility. Their durable construction and small mesh size act as a reliable barrier, protecting against insects, rodents, and other unwanted visitors, thereby safeguarding the integrity of the food products.

Optimal Equipment Protection:

Food processing facilities house a wide range of expensive and sensitive equipment that requires protection from physical damage and contamination. Welded wire mesh panels are used to create enclosures and barriers around equipment, preventing accidental contact or interference during the processing or cleaning procedures. These panels serve as a safeguard, prolonging the lifespan of the equipment and reducing the risk of product contamination.

-

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China